strictly

Junior Member

- Messages

- 55

Hi All,

Thanks to this forum I learned alot about GT subframes before buying a GT. Really great resource, and posts to forwarn! Mine looks good, I am only just starting to work on my GT, and have decided to start with a some preventative work on my front and rear subframes, while it is off the road for the winter.

My questions are:

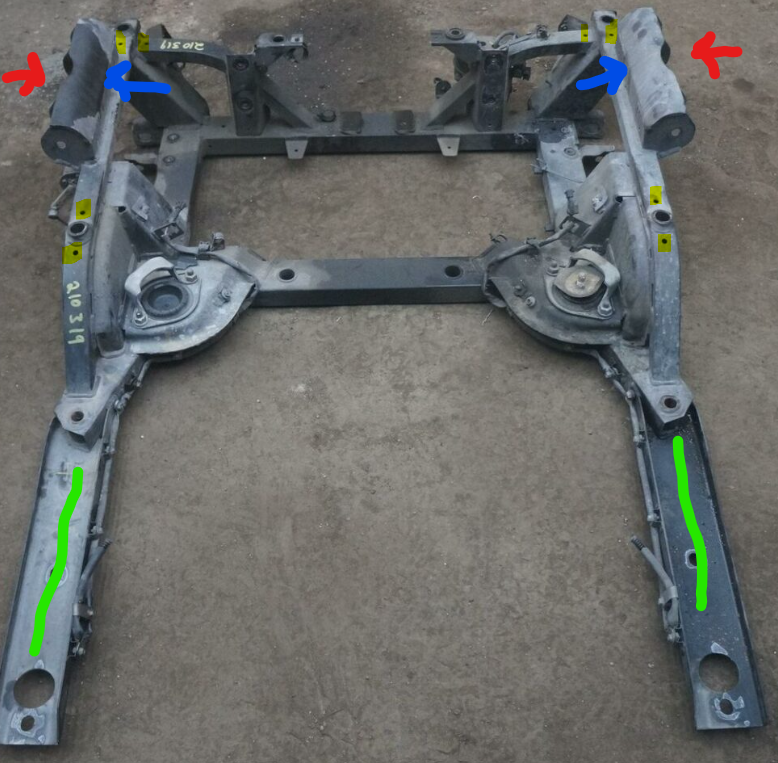

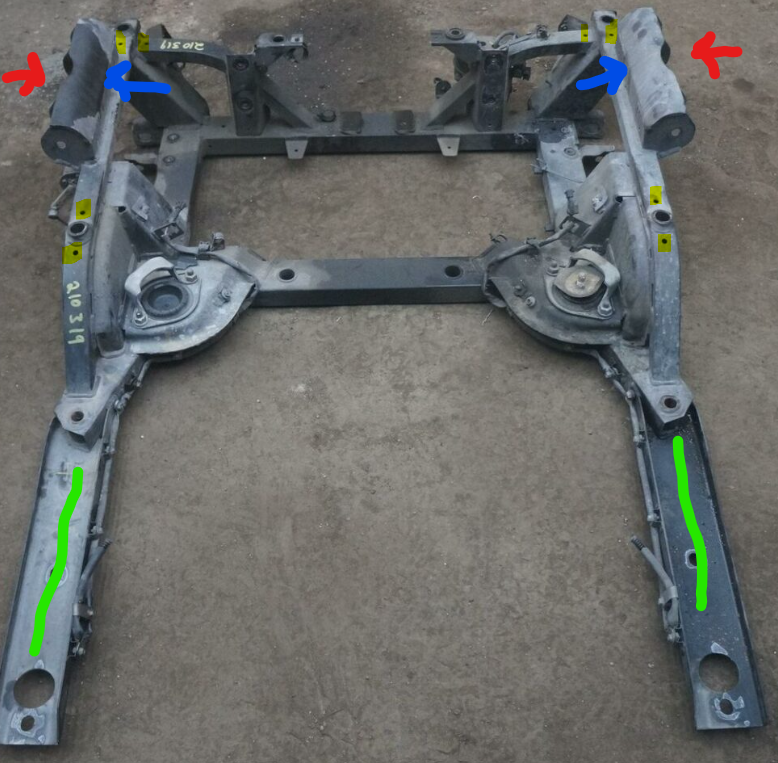

The subframe below is not mine, just a picture from the internet. I will post pictures of mine, as I do any meaningful work to share.

I have similar questions about the rear subframe, but will focus on the front first.

Thanks to this forum I learned alot about GT subframes before buying a GT. Really great resource, and posts to forwarn! Mine looks good, I am only just starting to work on my GT, and have decided to start with a some preventative work on my front and rear subframes, while it is off the road for the winter.

My questions are:

- Should the subframes be drilled on the bottom in places where there is a "box section" areas for wax injection?. These holes could then be plugged or left as a drain?

- I think i read that one of the reasons they rust is because they have holes in the top that let water in....Is this true? I have marked some in the picture below in "yellow highlight". I have not yet checked directly on my car if these are actual holes or if these have bolts in them. If these really are holes directly into the subframe, they could be used for wax injection rather than drilling new ones.

- In the picture below, i have marked in blue where I know they rust (in between the top wishbone mounts). Should this "triangular box section" be drilled? I have also read they rust behind this (marked in red). Where else should i check for rust? Is there another hidden area that they rust?

- The legs which i marked in "green", they look like they would retain water....but perhaps they are angled on the car so its not a problem. Again is this a good place to drill some drain holes? or just "flood area" with a wax?

The subframe below is not mine, just a picture from the internet. I will post pictures of mine, as I do any meaningful work to share.

I have similar questions about the rear subframe, but will focus on the front first.