Rear hub diassembly

Thanks, I got so much help from reading the forum, I hope to contribute back something useful too. So here it goes then. I started with a spare hub as an experiment (indeed I broke the plate as seen above)

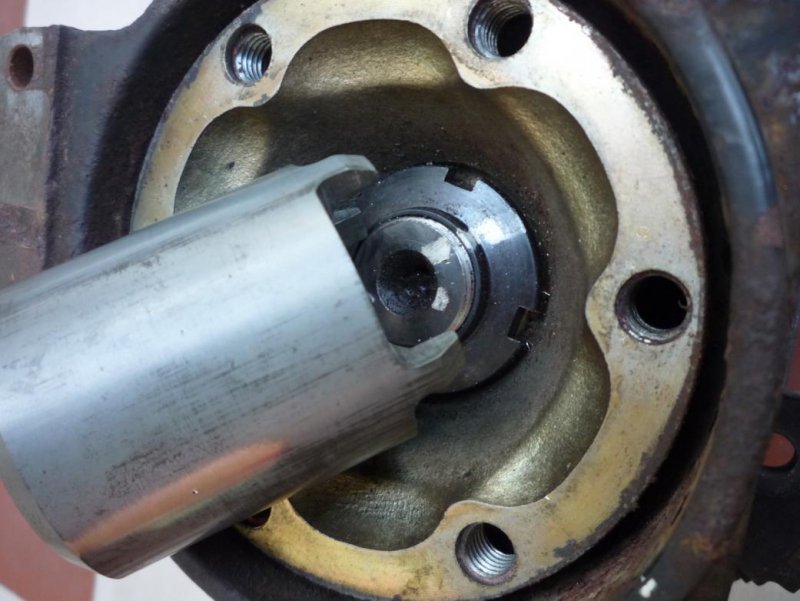

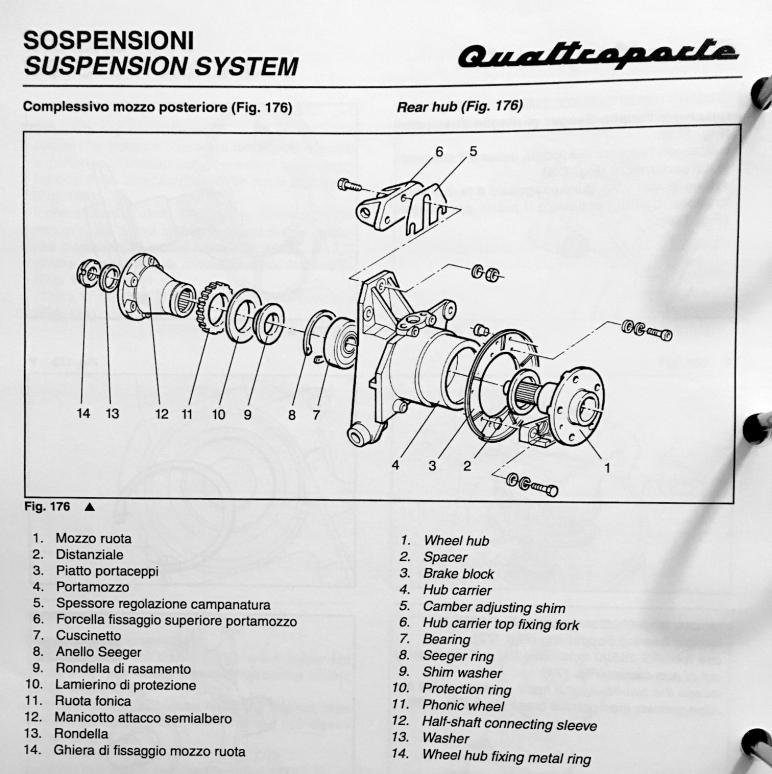

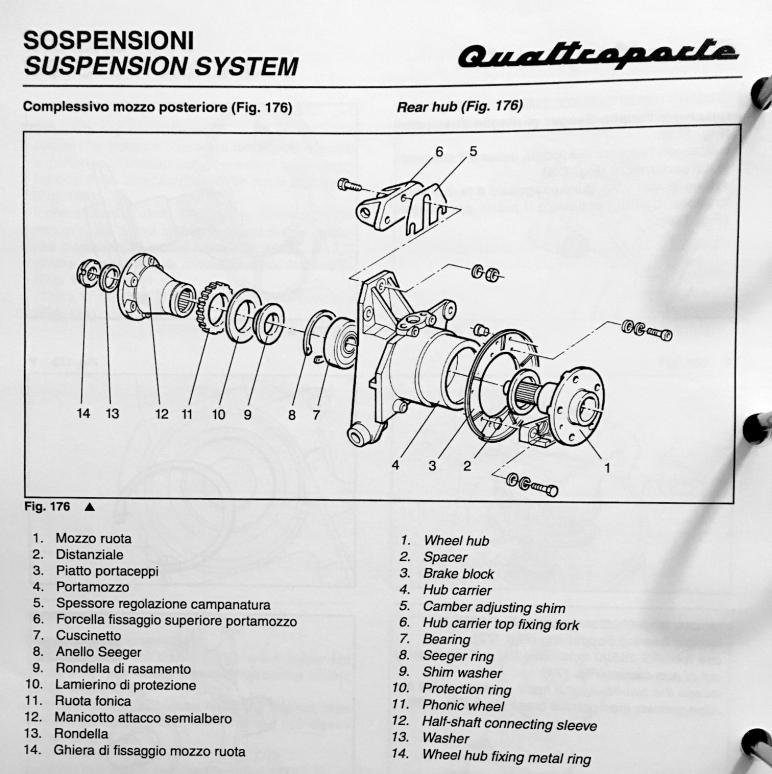

I wanted to weaken the ring nut (14) which I got stuck last time, but it turned out it just needs more torque to open, by the manual it has to be torqued to 30 kgm.

The washer (13) and the sleeve (12) together with the phonic ring (11) and the protection ring (10) will just slide down from the hub shaft.

There is a big seeger ring (8) which will probably needs some force to remove because of the corrosion inside.

The washer on top of the bearing (9) might simply slide down if the hub is turned upside-down, or will be removed after the hub is pushed out. Which is the second most hardest part. You have to unscrew the brake shoe holding plate (3) from the hub first. The screws will be either corroded, or have some thread locker on them. So definitely apply a lot heat to break up these, especially for the allen head ones, which are quite easy to strip. I even broke one which holds the ABS sensor, welded a nut on it, and the heat lossened it nicely.

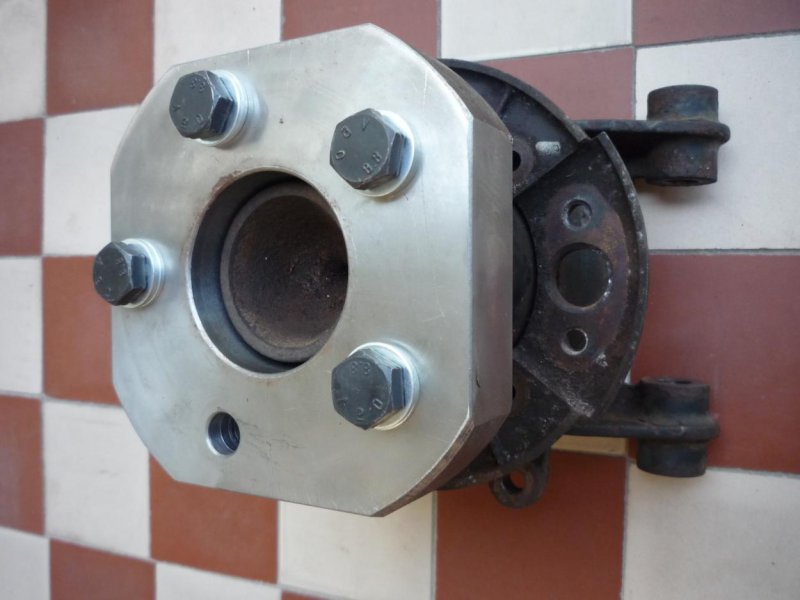

To push out the hub (1) support the hub carrier itself (4) and

not the brake plate which is from a really rigid and fragile alloy. Also be prepared that the balls of the bearing will fall out, put some clothes below to catch them.

The bearings (7) are double row ball bearings, SKF BAH-0004 A, the inner race of the outer row will stay on the hub shaft.

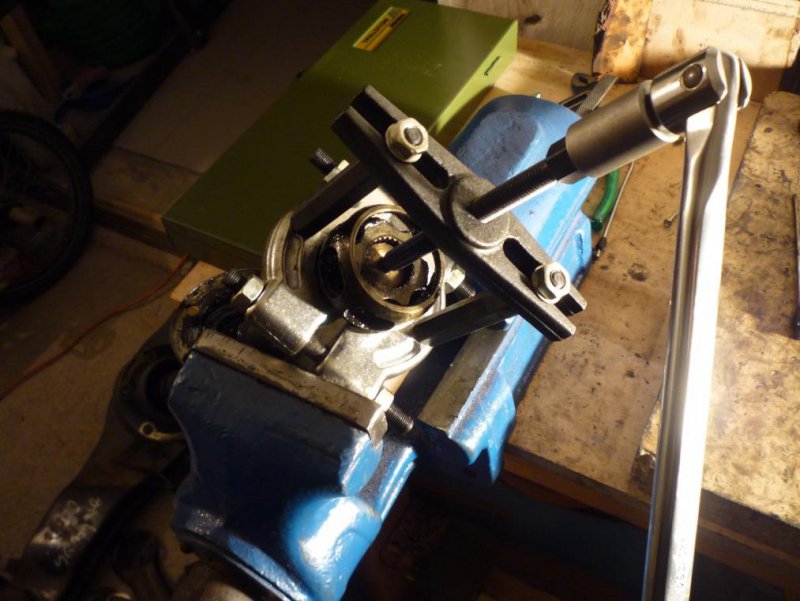

The outermost part of the bearing can be removed before tackling the inner race.

Removing the inner race was the hardest / most frightening part for me. I'm sure there are various methods for this, I choose to cut two groves with an angle grinder and use a bearing separator to pull down the race.

After it's down the spacer (2) will simply slide down.

Finally pushing out the outer race is pretty easy with a properly sized tool which sits on the lips of the outer race.

Now the hub carriers are ready to be properly refinished. I'm still waiting for the damaged sleeves of the arm and hub to be repaired. Then will take everything to the painter. I'll probably go with some epoxy primer + 2K topcoat, because of the Tectyl in the subframe is not really compatible with the baking process of the poweder coating.

Couldn't decide though what is the original method, there is no primer below the black layer, but also doesn't look so thick as powder coat.