You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3200 Diff Seals

- Thread starter Lozzer

- Start date

Rex B

Member

- Messages

- 657

I can’t find it in the manual but l have removed a driveshaft from mine and this needs to be done to get to the seal . So let assume the process would be:1/ remove large nut holding the drive shaft to outer hub bearing. I think this requires a 32mm socket and a substantial bar.( best done with the wheel on and car on its wheels) 2/ next jack up car and remove the wheel and then the 6 bolts holding the driveshaft inner cv to the diff. 3/ You then have to disconnect one end of the drop link from anti roll bar and this then allow you enough room to remove the driveshaft. 4/ Having removed the driveshaft you now have access to the hub which looks like it is attached to the diff with a centre bolt. It looks like this is then removed allowing the hub to be removed . 5/ Once removed you should have access to the seal which can then be removed and the a new one gently pushed and tapped back in. 6/ Reassembly is a repeat of removal but you do need a large torque wrench to tighten the driveshaft nut to the outer hub bearing 320Nm . You should also consider fitting a new outer nut and driveshaft locking bolt plates when refitting the driveshaft. Also don’t forget to refill the diff with oil.

Lozzer

Member

- Messages

- 2,285

Thanks RexI can’t find it in the manual but l have removed a driveshaft from mine and this needs to be done to get to the seal . So let assume the process would be:1/ remove large nut holding the drive shaft to outer hub bearing. I think this requires a 32mm socket and a substantial bar.( best done with the wheel on and car on its wheels) 2/ next jack up car and remove the wheel and then the 6 bolts holding the driveshaft inner cv to the diff. 3/ You then have to disconnect one end of the drop link from anti roll bar and this then allow you enough room to remove the driveshaft. 4/ Having removed the driveshaft you now have access to the hub which looks like it is attached to the diff with a centre bolt. It looks like this is then removed allowing the hub to be removed . 5/ Once removed you should have access to the seal which can then be removed and the a new one gently pushed and tapped back in. 6/ Reassembly is a repeat of removal but you do need a large torque wrench to tighten the driveshaft nut to the outer hub bearing 320Nm . You should also consider fitting a new outer nut and driveshaft locking bolt plates when refitting the driveshaft. Also don’t forget to refill the diff with oil.

Oneball

Member

- Messages

- 11,117

Why are you bashing the circlips ? Use a circlip pliers to easily remove & replace them.

Its not a circlip that you are “bashing” at.

There’s a wire spring clip on the end of the shaft that fits in a grove in the diff. This is what retains it in the diff in place of a bolt in the diagram. This is what you’re trying to release.

Lozzer

Member

- Messages

- 2,285

Ahh, thanks TimIts not a circlip that you are “bashing” at.

There’s a wire spring clip on the end of the shaft that fits in a grove in the diff. This is what retains it in the diff in place of a bolt in the diagram. This is what you’re trying to release.

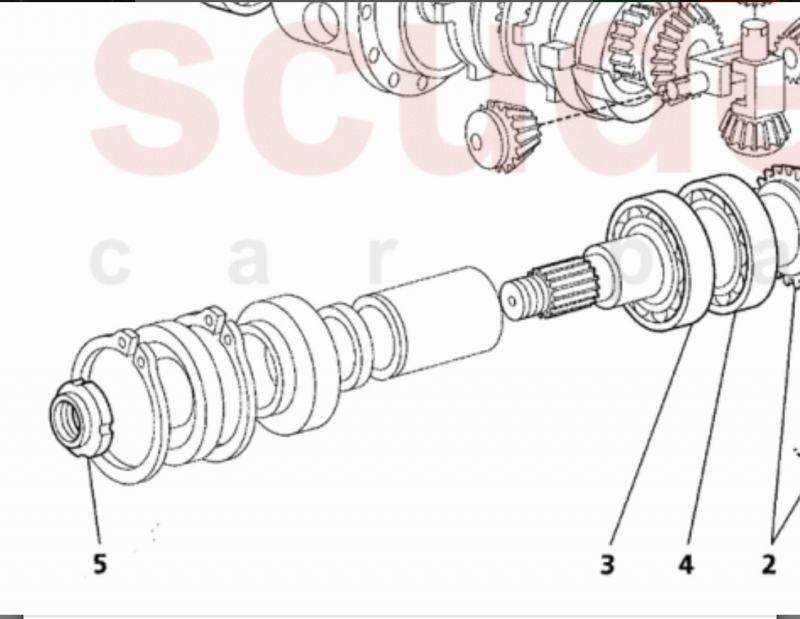

View attachment 98188

Last edited:

Oneball

Member

- Messages

- 11,117

Where would this accessed from?

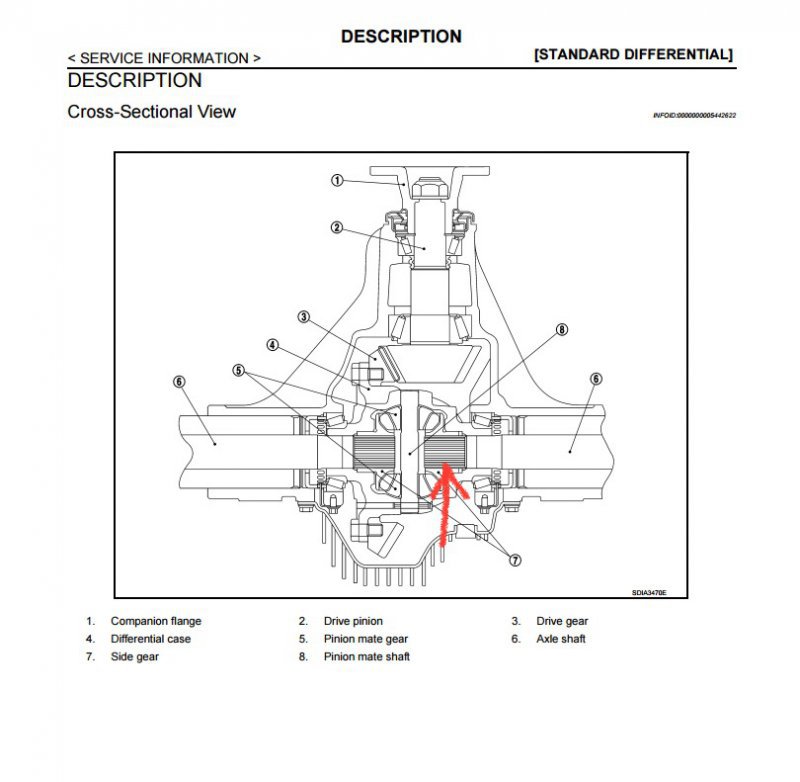

You can’t get to it. It’s inside the sun gear. This pic is a live axle so the shaft is retained by the wheel bearing but is if it was a wire clip it’d be here.

All it is is a piece of spring wire in 2 grooves. The force you apply to the shaft compresses it in the grove so it’s diameter decrease and it releases from the groove in the sun gear.

Oneball

Member

- Messages

- 11,117

There are special tools for this sort of thing but I’ve never used one, this was given to me years ago by some who said they’d never used it and neither have I.

This is what I use.

You’re going to have to use your imagination here. Place the chisel between the output and case.

And lever the output away from the case so you tension the clip

Then hit the chisel with a hammer.

You have to tension the clip or it doesn’t work, there is a knack to it. If it hasn’t popped out after two blows. Tap the out put back in, it’ll only move a few thou and turn the output 1/2 or 1/4 turn as the clip is probably cocked

This is what I use.

You’re going to have to use your imagination here. Place the chisel between the output and case.

And lever the output away from the case so you tension the clip

Then hit the chisel with a hammer.

You have to tension the clip or it doesn’t work, there is a knack to it. If it hasn’t popped out after two blows. Tap the out put back in, it’ll only move a few thou and turn the output 1/2 or 1/4 turn as the clip is probably cocked