FIFTY

Member

- Messages

- 3,100

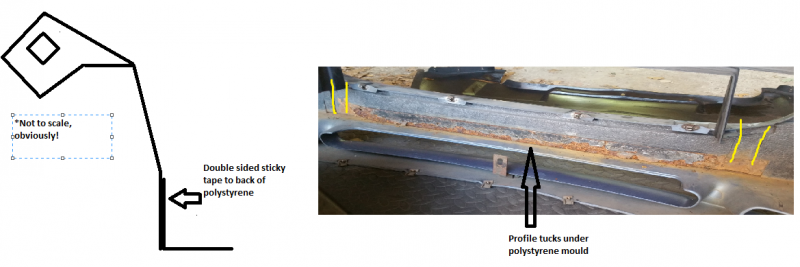

Not good news guys, seems like there is a bit of a design flaw with the main front bumper bracket where water pools under the polystyrene and the L shape part of the bracket which tucks underneath and eventually it rots spectacularly... the rust has spread onto the front accident brace. I have cought it before it went through thankfully it is still on the surface on the brace but the bracket is totalled (mild steel)

I need to get one fabricated out of stainless. Do you think the people who laser cut my exhaust flanges can help? I am worried they might ask for a CAD drawing and I have no clue... if anyone has the skills and some spare time I can take measurements!

I reckon as these cars are clocking over 15 years old they need a little extra care. Unless yours has been a garage queen only out on dry days it will probably look the same.

Here are some photos, the long rusted strip on the back of the bumper and the broken brackets are what is left. Loads of shards of rust tucked under the polystyrene that I cleared out. The bracket has a 3m double sided sticky tape backing

I need to get one fabricated out of stainless. Do you think the people who laser cut my exhaust flanges can help? I am worried they might ask for a CAD drawing and I have no clue... if anyone has the skills and some spare time I can take measurements!

I reckon as these cars are clocking over 15 years old they need a little extra care. Unless yours has been a garage queen only out on dry days it will probably look the same.

Here are some photos, the long rusted strip on the back of the bumper and the broken brackets are what is left. Loads of shards of rust tucked under the polystyrene that I cleared out. The bracket has a 3m double sided sticky tape backing