One other aspect is how much they will sell from these parts, 991s have great support but its one of the 911 series was build close to the 200k pieces, meaning that they have at least 150k owners as potential customers. 3200gt which was a successful model sold only 4,5 k pieces, if you assume that 20% is written off, then the potential clientele is less than 2% of the 911’s.

Obviously there is a financial scale that they need to consider and if they decide to produce only 500 throttle bodies, then these can be extremely expensive, so expensive that none will end up buying them. Everyone complains about the wishbones or the throttle bodies, but if they end up selling each one at 20-30% of the car’s resale value, then nobody is going to proceed.

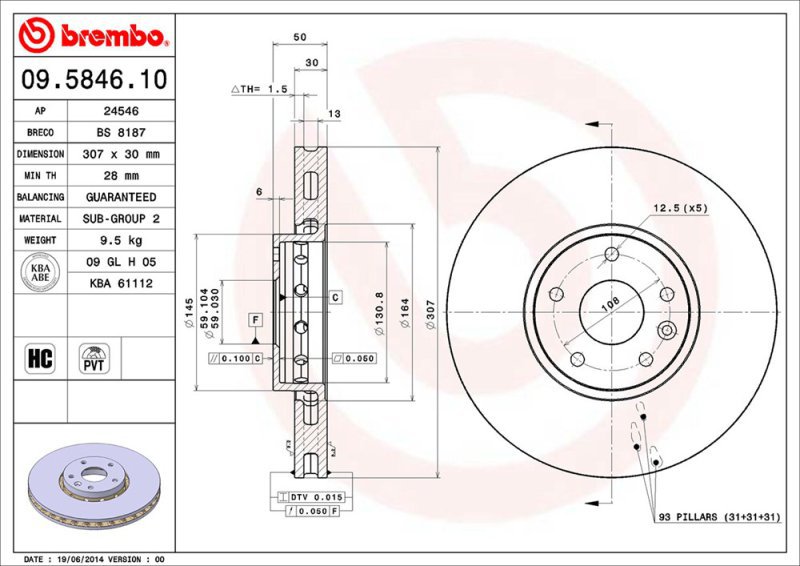

Ghibli 2 is a popular model and produced 2k cars, how many are out there? 500? How many brake disks they have to produce to support the market? 500 sets max? And all the models used the same brake disks across the range ?

Starting production of brake disks all over again is going to be expensive and lets not start taking about the hundreds of other parts that are not needed so often, we are talking about producing quantities of less than 50 pieces and some of them need to be considerably ”fresh” in order to work properly (So they will need to produce them again after a couple of years) Then you have models like Shamal and others…

If this project goes ahead successfully and IF Maserati owners start supporting their cars with original parts then i bet that old Maserati models will start having the appeal of the F cars and the Porsches. Although, I doubt that this will happen, i just can’t see many UK owners (which is a super important market for Maserati) with the resale value that their cars have, spending that amount of money.