OK so an update.

I now have in my possession a new release bearing which is below in various states of disassembly.

It breaks down (using a small flat bladed screwdriver to prise off the clips) into the following pieces:

1. Main Bearing Body

2. Clips

3. Retaining pin

4. Spring (the wavy washer)

5. Plastic bush/insert

The part which fails is the main bearing body as it is pressed from about 18 gauge steel, and has been quite distressed to form the bearing case shape, let alone retain its strength.

When your clutch fails, it is most likely because one of the lugs on the side of the body has snapped off.

When you press your clutch pedal, all of the release force is taken through the two lugs. Given the mechanical leverage your pedal and the hydraulic actuation provide, this is one heck of a lot of force for a thin piece of bent steel.

So lets look at why the bearing breaks before your clutch is actually worn out:

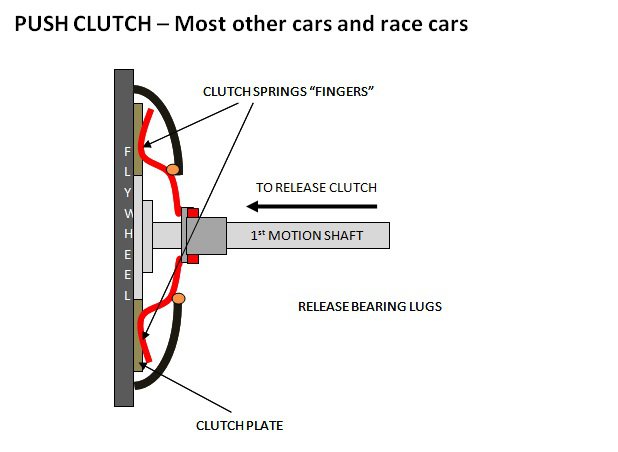

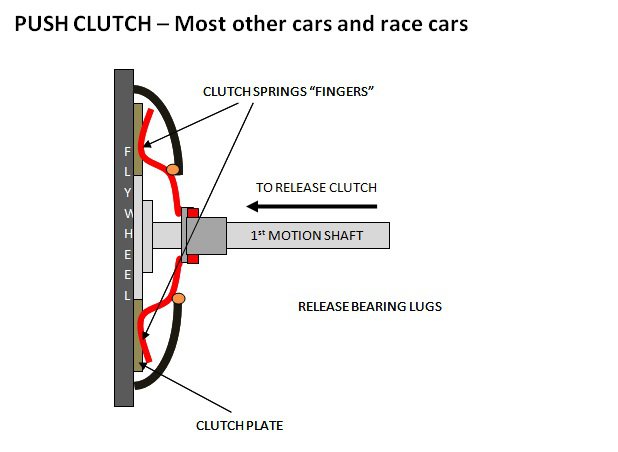

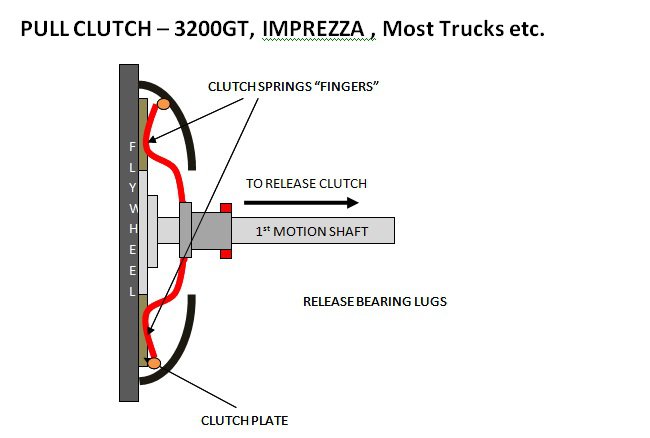

A push clutch moves the bearing towards the flywheel. The lugs the clutch arm operates on are supported by the actual bearing which sits on the clutch fingers. It is a much stronger design. Those with a keen eye will notioce the fulcrum point fo the fingers is halfway along the finger instead of on the periphery of the clutch as it is on a Pull Clutch. Because of this, the clamping force of the clutch for a given finger section/length is weaker. If it was on a truck instead of a 3200GT it

might slip.

Push clutches are used on race cars right up to F1.

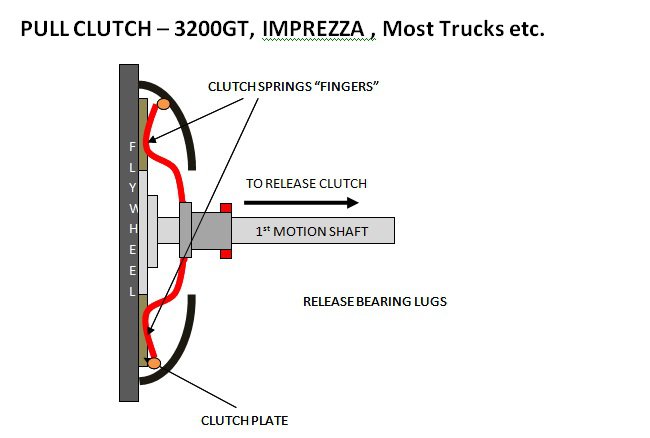

On the 3200GT then we are forced to use a pull clutch.

The pull clutch requires that the full load to release the clutch is borne by the lugs alone, hence they are under far greater stress. If you have ever removed the clutch from a lorry, these lugs are big chunks of cast steel, not something pressed out of flat sheet. With me so far??

So what happens as your clutch plate wears down?

So what happens as your clutch plate wears down?

Now this is the critical bit. Maserati claim the clutch plate must be changed when it wears from its original 9.0mm thickness to 8.5mm. The reality is the clutch plate will not fail until it wears so much the rivets score the flywheel. To reach this point it will be more like 5 or 6mm thick.

What is key however, is that the thinner your clutch plate, the further distance the release bearing must move between the fully released position, and where the springs are fully loaded onto the plate to provide drive.

If your 3200GT is hard to get in gear when stationary (especially reverse) then its because your drive plate is wearing - it is however far from worn out.

Maserati know there is a problem with the weakness of the release bearing, which is why the workshop manual goes to great lengths to set up the position of the pedal stop and the length of the slave cylinder pushrod. These processes are so you get an issue selecting 1st or reverse, before your bearing lugs snap and you are stranded at the side of the road.

The bearings are more prone to break if you adjust the pushrod or pedal stop to get a bit more life from your otherwise fully serviceable clutch.

The bottom line is that if we can make the release bearing stronger, we can extend the life of the clutch. Probably to double or triple what seems to be the normal 20k miles.

Lets go back to my pic and look at two parts:

1. Main Bearing Body

5. Plastic bush/insert

I have this morning examined the options for the bearing body and feel the best approach is to replace the plastic bush/insert.

Currently, any load supported by the lugs on the Main Bearing Body gets transferred to the Plastic bush/insert, but because this is a) Plastic and b) not mechanically attached to the Main Bearing Body except for by the small clips which have little strength, really the strength of the entire setup is down to the sheet metal from which the Main Bearing Body is pressed.

We have already discussed this is not robust.

I have therefore costed out making a kit which comprises a newPlastic bush/insert which is made from steel, with a bronze internal liner to protect the first motion shaft. This new insert is welded to the lugs and welded to the Main Bearing Body.

It is much stronger, and cannot fail to last longer than the 12-20k miles most get from a clutch

Its not going to be cheap, but it almost certainly will extend clutch life dramatically.

If you can find someone to remove your gearbox and fit a new clutch for less than £800, you have done well. With the best price on clutch kits being £500, by the time George Osbourne takes his cut you are into a minimum of £1560, probably more.

The process to upgrade would require you to send me a new bearing and I will return you an modified new bearing by return post. I would expect the cost to the upgrade to the bearing to be about £200.

So is anyone interested ? I need a minimum of 5 interested parties to make this happen.