Fat Arnie

New Member

- Messages

- 428

Well, a good soak with GT85 and the mother of slide hammers (7kg weight, 1m long!) has made no difference.

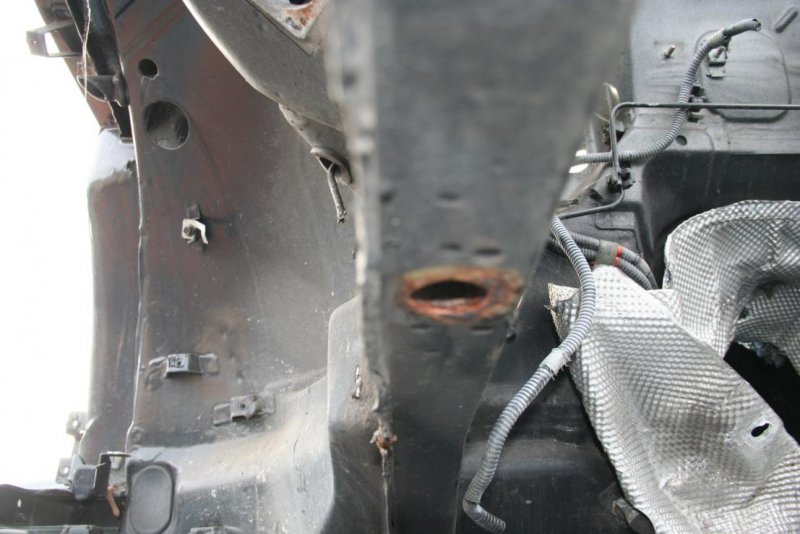

The LHS of the subframe is completely free, and the RHS is free at the front and rearmost points - a pry bar allows the subframe to be pulled away due to its natural flex.

The subframe appears stuck due to the bush that inserts into the chassis stanchions.

Last resort before the angle grinder and a new subframe is some Wurth Rost Off Ice. Unless anyone has any other ideas. Heat isn't really an option.

The LHS of the subframe is completely free, and the RHS is free at the front and rearmost points - a pry bar allows the subframe to be pulled away due to its natural flex.

The subframe appears stuck due to the bush that inserts into the chassis stanchions.

Last resort before the angle grinder and a new subframe is some Wurth Rost Off Ice. Unless anyone has any other ideas. Heat isn't really an option.

![IMAG0522[1].jpg IMAG0522[1].jpg](https://www.sportsmaserati.co.uk/data/attachments/33/33000-d081423b18212a21ff413aaa00be9e90.jpg)