You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Indicator issue

- Thread starter AG2728

- Start date

richard_masa_4200

Junior Member

- Messages

- 195

Mine definitely needed a puller when I took it off.

When you do get it off make sure you don't turn the clock spring wheel too much. It is centred. The plastic pin that sticks through the boss should stop it moving past centre, but not always. When you replace the boss the 2 splines from the clock spring must marry up with the white indicator cancel fitting. You'll see what I mean once you get the boss off.

When you do get it off make sure you don't turn the clock spring wheel too much. It is centred. The plastic pin that sticks through the boss should stop it moving past centre, but not always. When you replace the boss the 2 splines from the clock spring must marry up with the white indicator cancel fitting. You'll see what I mean once you get the boss off.

AG2728

Member

- Messages

- 120

Well as you can see, I have made myself a puller.

It's a sturdy disc turned from 8mm plate secured with 4x M6 bolts through the original wheel mounting points. It has an even sturdier M21 bolt which I have lathe turned to fit into the rebate in the column.

However, even swinging as hard as I dare on a 10 inch long 1/4 drive bar it has shown no signs of moving.

Can any of you guys who have needed the use of a puller give me some idea of how tight yours was?

If this was a P reg Tranny van I would doubtless continue to apply more force and if it broke I would just wander down to the nearest scrapyard and get another. But it isn't and I can't.

I am not usually the indecisive type but at this point in time, I cannot decide whether I am being a bit of a tart in being too gentle because its my P&J with a horrific reputation for replacement parts costs or if I am being really sensible in not going ballistic on it.

Any thoughts gents?

It's a sturdy disc turned from 8mm plate secured with 4x M6 bolts through the original wheel mounting points. It has an even sturdier M21 bolt which I have lathe turned to fit into the rebate in the column.

However, even swinging as hard as I dare on a 10 inch long 1/4 drive bar it has shown no signs of moving.

Can any of you guys who have needed the use of a puller give me some idea of how tight yours was?

If this was a P reg Tranny van I would doubtless continue to apply more force and if it broke I would just wander down to the nearest scrapyard and get another. But it isn't and I can't.

I am not usually the indecisive type but at this point in time, I cannot decide whether I am being a bit of a tart in being too gentle because its my P&J with a horrific reputation for replacement parts costs or if I am being really sensible in not going ballistic on it.

Any thoughts gents?

2b1ask1

Special case

- Messages

- 20,275

Just a thought but did you turn the end of the bolt down so it doesn't spread and jam the thread or worse the end of the steering column? other then that I would suggest adding a counter lever bar to the bolts holding the plate so you can 'give it some welly' without working against the steering lock...

Final suggestion is to swap the T-bar for an impact driver (good old traditional type) as it may just shock it enough

Final suggestion is to swap the T-bar for an impact driver (good old traditional type) as it may just shock it enough

CatmanV2

Member

- Messages

- 48,796

Well, when I did the wheels Ive removed they were tough. I'm not sure how hard you 'dare' though....

FWIW when I did my wipers, I had to use an 8" spanner on the 'hand wheel' to get the thing to crack off. If course, once it's moving, it's all good.

Looking at your rather super puller, I expect you could put 'quite a lot' of force on that without risking damage. Having said that, the boss (according to eurospares) is only available as part of the wheel. And there's no price...

If you're worried, why not ask David Askew or similar how much a boss or wheel would be, and maybe get a spare in.

The diagram is pretty clear, though. There's nothing else that looks as though it's holding the wheel / boss on.

C

FWIW when I did my wipers, I had to use an 8" spanner on the 'hand wheel' to get the thing to crack off. If course, once it's moving, it's all good.

Looking at your rather super puller, I expect you could put 'quite a lot' of force on that without risking damage. Having said that, the boss (according to eurospares) is only available as part of the wheel. And there's no price...

If you're worried, why not ask David Askew or similar how much a boss or wheel would be, and maybe get a spare in.

The diagram is pretty clear, though. There's nothing else that looks as though it's holding the wheel / boss on.

C

AG2728

Member

- Messages

- 120

Newton.

Yes I turned the end of the centre bolt and I am not putting stress on the steering lock. That is why the key is in the ignition. I have also prevented the boss from rotating by using a lever across the bolt heads. Maybe you are correct and it will take an impact driver to shock it. I am just amazed as its a bloody wheel boss, not a wheel bearing I am dealing with. How tight does it really need to be FFS?

I will have to retire in defeat for now and review the situation with less tired eyes tomorrow? Thanks for the input. I am determined not to be beaten by what should be such a simple task.

Yes I turned the end of the centre bolt and I am not putting stress on the steering lock. That is why the key is in the ignition. I have also prevented the boss from rotating by using a lever across the bolt heads. Maybe you are correct and it will take an impact driver to shock it. I am just amazed as its a bloody wheel boss, not a wheel bearing I am dealing with. How tight does it really need to be FFS?

I will have to retire in defeat for now and review the situation with less tired eyes tomorrow? Thanks for the input. I am determined not to be beaten by what should be such a simple task.

Last edited:

AG2728

Member

- Messages

- 120

Catman

It's not the puller I am worried about, I made it tough enough to survive a nuclear holocaust.

If I knew what the back of the boss looked like I may not be as concerned as I could probably make one if it doesn't have too many complex or asymmetrical details.

One thing that is certain though is that Sod's law states that if I do manage to break it, the back will no doubt incorporate the most complex and asymmetrical details known to man, I will get depressed and have to spend lots of money.

I am however encouraged to hear your experience of how tight these can be and will awake with renewed vigour and more courage to lean on it a bit more.

It's not the puller I am worried about, I made it tough enough to survive a nuclear holocaust.

If I knew what the back of the boss looked like I may not be as concerned as I could probably make one if it doesn't have too many complex or asymmetrical details.

One thing that is certain though is that Sod's law states that if I do manage to break it, the back will no doubt incorporate the most complex and asymmetrical details known to man, I will get depressed and have to spend lots of money.

I am however encouraged to hear your experience of how tight these can be and will awake with renewed vigour and more courage to lean on it a bit more.

Last edited:

Phil the Brit

Member

- Messages

- 1,499

"Shocking" it off is the answer. Hit the pry bar with a hammer.

AG2728

Member

- Messages

- 120

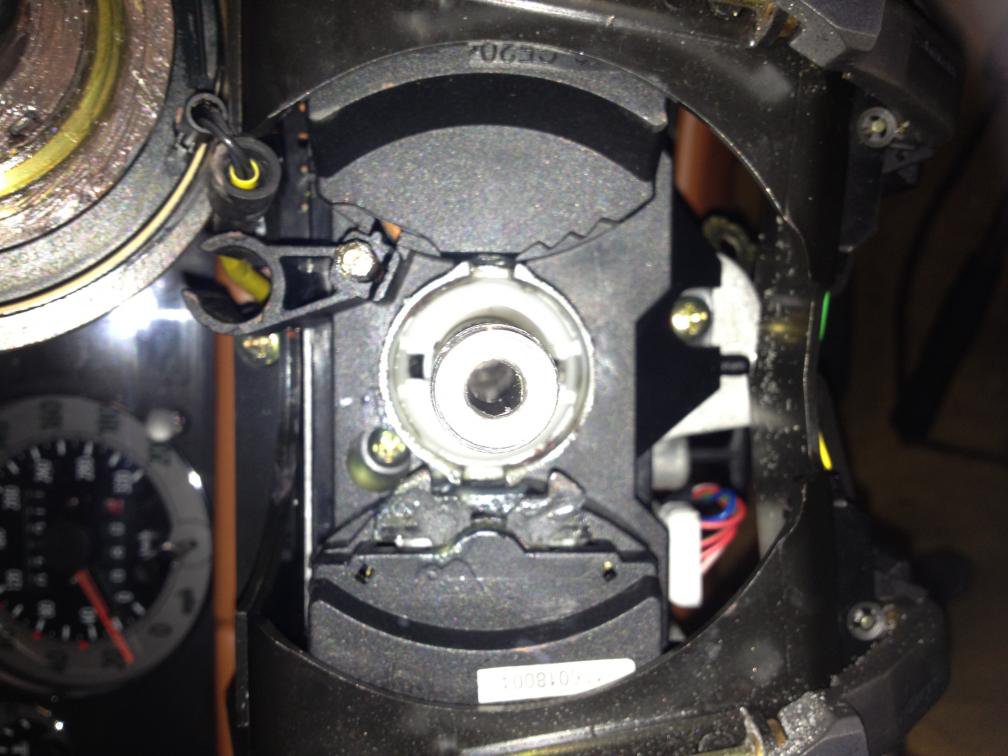

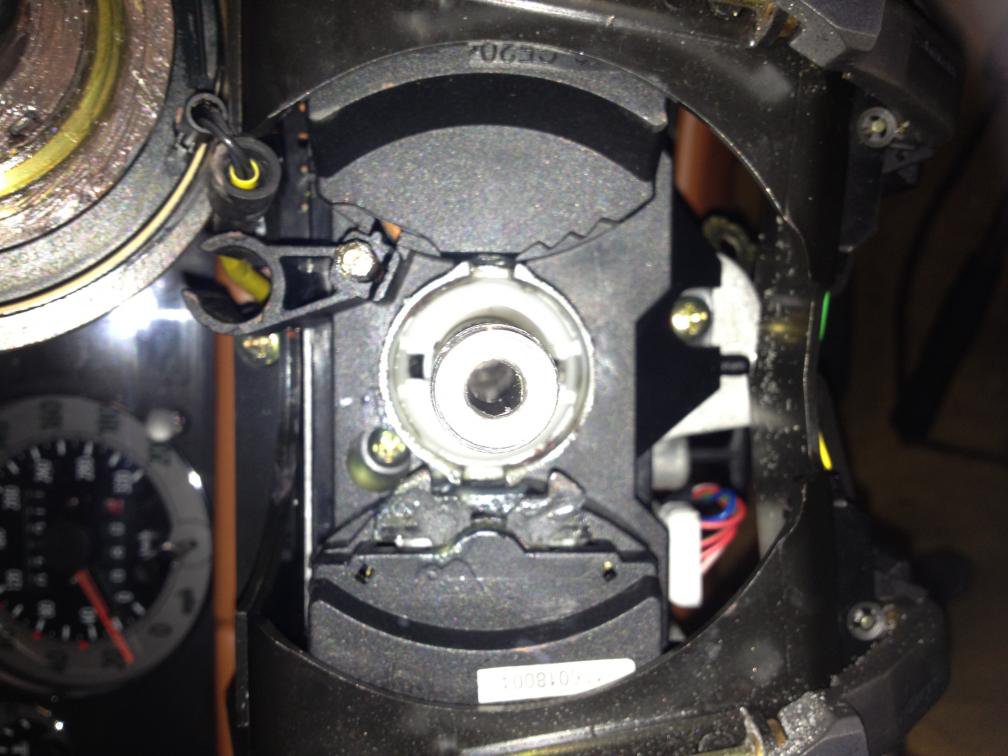

After much encouragement last night from this forum, I approached the task with great vengeance and furious anger using a bigger hammer... et voila!

It was very, very tight and came unseated with an almighty and somewhat disturbing crack. Everything is intact though, so all is well.

For reasons unknown to me, the photo above has decided to load itself sideways, so the left side of the pic is in fact the top of the mechanism. I can see that the lobes on the white ring sit at 3 and 9 o'clock, when the steering is in the straight ahead position. Earlier in the thread, it was suggested that these lugs should maybe sit at 6 and 12 o'clock but I am not certain about this now.

There does seem to be a lot of play in the whole mechanism but I will need to remove and strip it to investigate further as unfortunately when it is in situ it needs the hub and the wheel attached in order to operate which means I can't see what it is actually doing.

A job for tonight, time permitting or I will get stuck in at the weekend.

Thanks again.

It was very, very tight and came unseated with an almighty and somewhat disturbing crack. Everything is intact though, so all is well.

For reasons unknown to me, the photo above has decided to load itself sideways, so the left side of the pic is in fact the top of the mechanism. I can see that the lobes on the white ring sit at 3 and 9 o'clock, when the steering is in the straight ahead position. Earlier in the thread, it was suggested that these lugs should maybe sit at 6 and 12 o'clock but I am not certain about this now.

There does seem to be a lot of play in the whole mechanism but I will need to remove and strip it to investigate further as unfortunately when it is in situ it needs the hub and the wheel attached in order to operate which means I can't see what it is actually doing.

A job for tonight, time permitting or I will get stuck in at the weekend.

Thanks again.

Last edited:

AG2728

Member

- Messages

- 120

Guess what?????? IT'S SORTED!!!!!

Sat looking at and playing with the thing for about 1/2 an hour and then re-read the whole thread.

Richard_Masa_4200 had said earlier in the thread:..........

When you do get it off make sure you don't turn the clock spring wheel too much. It is centred. The plastic pin that sticks through the boss should stop it moving past centre, but not always. When you replace the boss the 2 splines from the clock spring must marry up with the white indicator cancel fitting. You'll see what I mean once you get the boss off.

.........and at the time this was absolutely meaningless to me so I chose not to comment as I assumed he may have been taking recreational drugs or similar. Centred clock spring wheel indeed! In fact this statement proved to be the key to resolving my problems.

After removing the liberal coating of copaslip grease I could clearly see two arrow markers on the rear of the boss and the contact ring.

I have no idea what purpose they serve but are are obviously part of Richard's clock spring wheel centering theory. Upon lining them up, everything became misaligned by 90 degrees. I turned the mechanism itself round by 90 degrees so the cams and lobes were not aligned as they were in the photos posted by ChrisBassett and rebuilt everything up as I had nothing to lose but my time. Everything is now perfect. It has obviously been rebuilt incorrectly at some time in the past.

What I did find interesting (but then again I am a newbie) was the logo stamped into the back of the boss.

Another raid on the Alfa parts bin then.

I am now obviously basking in the warm glows of smugness and contentment after managing to resolve my issue at zero cost to myself and having been told my problem stemmed from the car having a non-genuine wheel. I can now strip and re-bond the airbag cover and the world will be a better place.

Thanks to all who have contributed to my success as I have found it really helpful. Sorry for any new potential forum members who may have popped in and seen 30+ posts involving some bloke who should get out more, wailing about the fact he thinks his indicators should cancel quicker. I admit after a re-read, it is probably the most anal thread subject on the site. But I'm happy.

Oh and if anyone is struggling to remove their steering wheel, you are more than welcome to borrow my Maserati special tool v1.01